As India bets big on green hydrogen, there is an interim solution

SUMMARY

The Council on Energy, Environment and Water argues that India can make the energy transition process easier and cleaner for now, by using natural gas pyrolysis.

By Sabarish Elango and Hemant MallyaIndia plans to go big on green hydrogen to reach its ‘net zero by 2070’ goal. However, it will take a while to build demand and scale up production. There is a way to make the transition easier and cleaner for now, using natural gas pyrolysis. This process can help natural gas consumers such as fertiliser plants, refineries and others start decarbonising since pyrolysis produces 84% less carbon dioxide, according to a recent study by the Council on Energy, Environment and Water (CEEW).

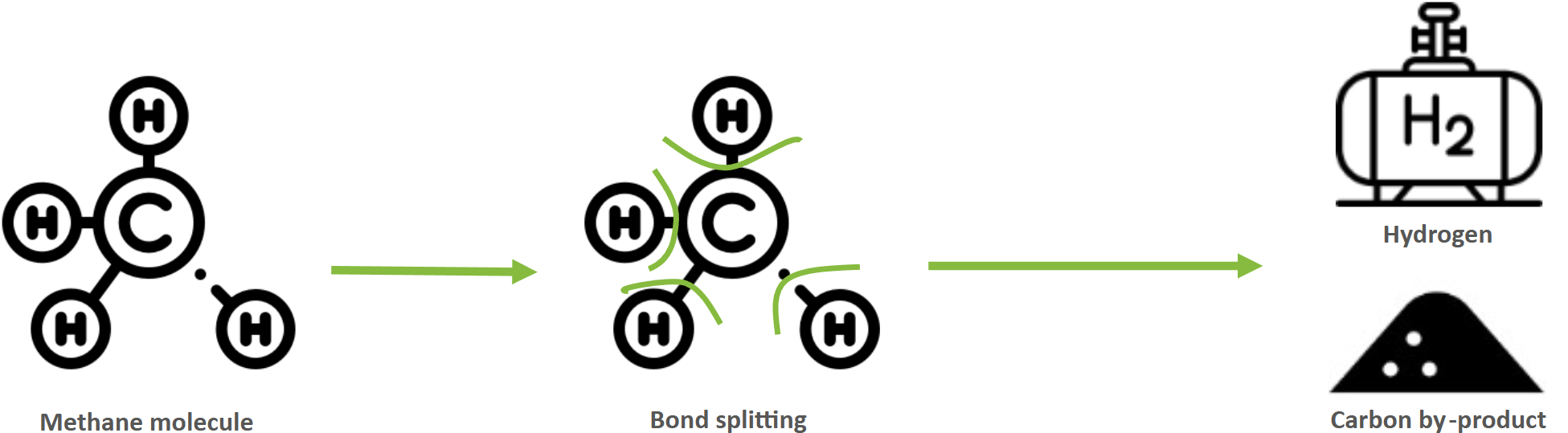

Pyrolysis of natural gas entails decomposition of methane at high temperatures to produce hydrogen gas and solid carbon particles. The hydrogen produced through pyrolysis is termed ‘turquoise’ hydrogen. It is better than the ‘grey’ hydrogen currently used in industries, which is derived from fossil fuels. Grey hydrogen is produced through the steam-methane reformation technology (SMR) that inherently releases process CO₂ alongside other emissions from heat generation. There are two sources of CO₂ in the SMR process — CO₂ from the reformation process and CO₂ from the heat supplied to enable the reaction. With pyrolysis, the former does not occur and CO₂ is released only from heating. Thus it is much cleaner.

Decomposition of natural gas through pyrolysis produces both hydrogen and solid carbon

In pyrolysis, the carbon comes out as a solid powder of high purity that can be used for other purposes. It can replace carbon black used in tires and dyes. It could potentially replace coke used in steelmaking. Some pyrolysis processes produce higher value carbon by-products like graphite, which is essential for battery manufacturing. The sale of this solid carbon by-product will offset the price of turquoise hydrogen. At USD 1.6 per kilogram, turquoise hydrogen will be half the price of green hydrogen currently, and is competitive with grey hydrogen.

Although natural gas pyrolysis is not yet practiced in India, it is a short- to medium-term solution until green hydrogen becomes accessible and cheap. Pyrolysis plants for turquoise hydrogen production are already operating in the United States, with one company running commercial operations and another running a commercial pilot successfully. Companies in many other countries including Australia, Germany and Finland are scaling up their commercialisation efforts.

The benefits are two-fold—demand-building for green hydrogen, and offsetting imports of carbon black and coking coal. To enable pyrolysis technology to scale-up, we make the following recommendations.

Scale up the hydrogen economy by accommodating turquoise hydrogen in purchase obligations until affordable green hydrogen is available at scale.

Carry out a pilot study to estimate the feasibility of hydrogen production through natural gas pyrolysis at a suitable location with natural gas availability and potential offtakers of hydrogen and carbon.

Blend turquoise hydrogen with natural gas to incrementally decarbonise the natural gas demand base. Deploying pyrolysis plants near existing pipeline injection points (liquefied natural gas terminals and gas processing sites) could offer the opportunity to seamlessly blend 15 per cent of hydrogen by volume.

Convert existing pyrolysis plants to use natural gas. Pyrolysis technology is currently used to produce carbon black using low-value residual oils. These plants could possibly switch to natural gas without significant investment.

Leverage new and existing markets for carbon by-products to offset the price of hydrogen. Pyrolysis carbon can supplement the domestic supply of carbon black. It could potentially substitute coke in blast furnaces for producing steel. It can also be used to produce carbon electrodes for the manufacture of aluminium. Another potential pathway is the production of activated carbon from carbon black. Carbon black can be used in the manufacture of sodium-ion batteries, while graphite can be used in lithium-ion batteries.

Turquoise hydrogen is much cleaner than grey hydrogen while being much cheaper than green hydrogen. Therefore, it is an ideal trade-off for building a market for hydrogen while simultaneously reducing India’s overall carbon emissions.