Kent prepares for HyNet delivery

SUMMARY

Kent's market director for low carbon projects gives Gas Pathways his thoughts on delivering Vertex's 1,000 MW hydrogen generation project, part of the HyNet North West Track 1 cluster sequencing initiative.

By Callum CyrusWith its prime minister Boris Johnson preparing to leave office, the UK now stands on the cusp of a new epoch for its energy policy, in line with its objective of achieving net zero by 2050. Low-carbon hydrogen production, distribution and fuel switching is a key pillar of this transition strategy. Following the publication of its new energy security strategy in April, Whitehall now aims to have delivered 10 GW of hydrogen production capacity by the end of this decade. That is double the 5 GW capacity it had originally envisaged. Around half of this quota is expected to come from green hydrogen, produced from renewable electricity sources, while the other 5 GW may be natural gas-derived blue hydrogen with carbon capture and storage, or alternatives such as nuclear-derived hydrogen or the experimental concept of turquoise hydrogen.

HyNet set to decarbonise England’s North West

At the heart of UK ambitions for industrial decarbonisation is the multi-track cluster sequencing programme. The cluster programme is designed to enable shared infrastructure and hydrogen production to be developed in a cost effective way. It prioritises the sequence of delivery underpinned by government support regime.

A large geographical area encompassing North West England and North Wales was identified as the one of the primary hot spots for industrial carbon emissions due to being home to the UK’s largest manufacturing region, employing nearly 350,000 people. Historically, this region is known as the global birthplace of the industrial revolution, which gave rise to the North West’s urban metropolises in Manchester and Liverpool, and the coal-mining pits that were once spread across northern Wales.

Today, the area retains the UK’s largest concentration of advanced manufacturing and chemical production facilities. It is a base as diverse as it is large - covering everything from food colourings to pottery, from glass to brick foundries and energy production. Industry in this region produce almost 40mn metric tons of carbon emissions/year.

Vertex Hydrogen is getting ready to deliver 1GW of low carbon hydrogen production capacity with production starting in just four years’ time. The £1bn ($1.2bn) development will anchor the decarbonisation of Liverpool and Manchester’s industrial heartlands, through HyNet, on an unprecedented scale - capturing 1.8mn mt of CO2 for permanent storage in the HyNet CO2 storage system.

Vertex Hydrogen is a joint venture between Indian conglomerate Essar and clean energy project developer Progressive Energy. Kent, the leading integrated energy services provider headquartered in UAE, was last month issued with the contract award for providing technical and consents advisory services to the Vertex project. The contract covers the first 350-MW production line, optimising the FEED design to meet the evolving project requirements. Kent will also lead on securing planning applications and consents, and providing the technical tender documentation for delivery contracts.

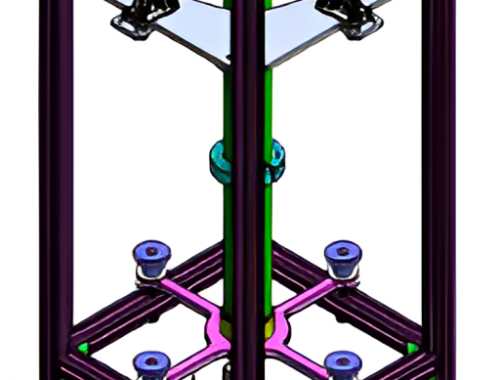

Kent’s market director for low carbon and onshore projects Matt Wills tells Gas Pathways the team worked closely with Vertex throughout pre-FEED and FEED design. Those efforts resulted in some major successes, notably producing a standardised template for building the foundations of the hydrogen plant, which could later be rolled out to other UK cluster facilities, reducing capital expenditures.

Wills said: “The team designed a standalone plant base - a cookie cutter plant that you could stamp out across the UK. This is a very good use of taxpayers money and gets the best value out of that work.”

“We’ve got a wide range of energy transition experience. We’ve supported something like two-thirds of the UK’s offshore wind, with our industry leading experience. We’ve got FEED to post-commissioning support experience too.

“We have many decades of CCS and CO2 experience in Canada - looking at some of the energy intensive production [centres] in the north of the country.

“What I’ve done is taken that expertise and knowledge, and brought it to the UK, to make best use of all that learning and experience so it is not wasted.

“And it helps the UK because we’ve not [yet] been successful in having commercial scale CCS here - so rather than [just drawing on] our own experience, let’s make best use of the experience in other markets.”

New Civil Engineering Magazine has described HyNet as the world’s most advanced low carbon hydrogen plant, and Wills says this is vindication of the UK’s joined-up approach to hydrogen delivery. The project will be based right next to Essar’s Stanlow Oil Refinery Complex, providing access to a ready-made engineering skills base to get the complex up and running.

“Companies want to take that hydrogen. It gives them a great pathway through to decarbonising, it also gives them the opportunity to have low-carbon products, which can be a key differentiator for their goods. That will help them remain relevant through the coming decades, as the UK heads towards net zero.”

The road to decarbonisation is all about innovation and collaboration across engineering houses. Wills says the importance of getting this right means that establishing best practices will define Kent's approach to projects such as HyNet, and this surpasses the industry’s competitive instinct.

“We’ve done a lot of work sharing our experience with clients in the UK, helping them be successful. We’re like that in the low-carbon industry. There’s a lot of [knowledge] sharing, we’re all trying to do something good to reduce the impact on the climate.

“[It is about] making sure the industry is successful, and it helps us all make a difference. We’ve done work on low carbon fuels and chemicals, plants all the way through to design and build. So we can feed that learning back into some of the work that we’d do in the UK. And put together all of that knowledge, the experience and skills, that has enabled us [Kent] to get through planning, engineering, design delivery projects, saving millions of tons of CO2 from going into the atmosphere.”

From a UK government standpoint, the incoming Conservative administration has a decent point of departure in terms of making the country a global hydrogen production powerhouse.

The UK’s Track-1 cluster sequencing process received five project applications to receive a share of the £1bn made available by Whitehall through its CCS Infrastructure Fund. HyNet in the North West and Wales was successful, as was the East Coast cluster. Both operators are now aiming to deliver the infrastructure to produce hydrogen and capture industry CO2 emissions by the middle of this decade. The East Coast cluster includes the ZeroCarbon Humber hydrogen production and CCS programme, as well as an onshore CO2 gathering, compression, utilisation and storage network in Teesside, and the Northern Endurance Partnership CO2 storage project.

A Scottish cluster, Acorn, was selected as a reserve project, meaning it has met the UK government’s evaluation criteria. The Scottish project will continue to be supported through the second phase of the UK’s cluster sequencing program, should the two track-1 projects proceed as anticipated.

Wills commended Whitehall for its work in supporting hydrogen innovation, but said he thought public policy could go even further to support industry in the early stages of tender bidding. Progressive Energy’s phase 1 submission paper notes that the revenue support model also needs to be firmed up for UK hydrogen projects as they approach FID-stage.

Wills said: “Until there’s a market, there is no private investment to support the development of projects. So until the government establishes a market and has that revenue support in place, it needs to provide that input to help the development of the front end of projects.

“I think the government has thought about [the energy transition] logically, especially around hydrogen. It’s a really clear, logical pathway. This work they’ve run themselves to put it through to private industry, and get that support. It's great and I think it's really set up the UK as a good place to do hydrogen.

“It’s been a beneficial process to expand our knowledge base in the UK. And there’s a good number of projects that are in development. Some are on Track 1, some are on slower tracks. But you can clearly see a great pathway of projects to keep us going in the UK, and get the country going towards net zero.”

Ultimately the UK's concept of delivering hydrogen output at scale is nascent and there will be big take-aways for the industry and government consider. Wills wonders whether state funding could have been put to better use in early cluster sequencing, perhaps by encouraging collaborations to standardise parts of the hydrogen delivery process, rather than taking a winner-takes-all approach.

“I mean, I can understand the need for competition, but I do wonder whether a bit more collaboration would have been helpful. And that might have enabled more projects to [have emerged] and been successful,” Wills said.

“So if there were quite a few hydrogen projects in play [in the bidding tender] could government have helped them get to the same sort of size - with a single cookie cutter design which could work across all of them?

“That might have enabled more projects to get closer to deliver. However, we got the competition process that was in place. And Vertex worked really hard to make sure they got ahead of the process, that they were ready as they can be for when the revenue mechanism comes into play.”