Veritas: getting a better grasp of methane emissions [Gas in Transition]

SUMMARY

Two years in the making, GTI launched Veritas in February this year, as “a set of standardised, science-based, technology-neutral, and measurement-informed protocols built to assemble methane emissions inventories that are verified by direct field measurements.” [Gas in Transition, Volume 3, Issue 7]

By NGWPOSTED IN:

Demand for lower-carbon LNG continues to grow, making it increasingly important for companies across the value chain for the super-cooled fuel to adequately measure and verify their methane emissions, a session at the LNG2023 conference in Vancouver heard on July 15.

US-based GTI Energy is working with the industry on establishing protocols for this task, programme manager Chris Moore said at a session. The organisation aims to release the 2.0 version of its Veritas methane emission measurement and verification initiative by the end of this year. Two years in the making, GTI launched Veritas in February this year, as “a set of standardised, science-based, technology-neutral, and measurement-informed protocols built to assemble methane emissions inventories that are verified by direct field measurements.”

Essentially, it seeks to provide companies and countries with an accurate and consistent approach to quantifying and verifying methane emissions across the natural gas and LNG value chain. GTI is not the only organisation endeavouring in this area. The Oil & Gas Methane Partnership 2.0, a UN-backed initiative with more than 100 partners and involving companies responsible for over half of the world’s oil and gas production, is also working on a gold standard for accurately and transparently reporting methane emissions.

“The objectives are to provide governments and the public with assurance that industry members’ methane emissions are being managed responsibly,” the vice president of regulatory affairs at the US’ largest LNG exporter Cheniere, Rob Smith, explained at the session.

As for Veritas, one of the challenges in measuring LNG-associated methane emissions is that there are few studies covering emissions at liquefaction and regasification terminals, Moore said. “The goal is really to get to an estimate that is based on at least 50% measurements but that's easier said than done.”

In order to broadly quantify methane emissions, the developers of Veritas have had to depend on emissions factors data available from the US Environmental Protection Agency (EPA).

“We know that they are probably inaccurate and they have a fairly large uncertainty associated with them that doesn't really ever get reported,” Moore said. “However, it's important to start with these numbers, and then build off of those our existing understanding of how much methane there is, because that's what we're tied to, in a regulatory sense and in a historical sense.”

GTI worked with Highwood Emissions Management and SLR Consulting and consulted with 36 industry, research, environmental NGO and financial stakeholders connected with the US natural gas sector to develop its protocols. “And we have taken feedback, they've had reviews, but at the end of the day, GTI Energy has the final say,” Moore said.

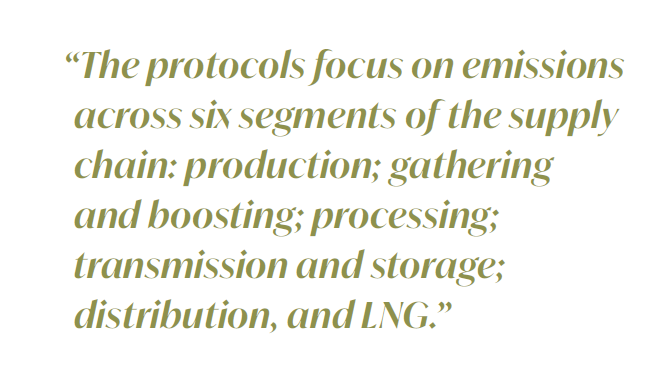

The protocols focus on emissions across six segments of the supply chain: production; gathering and boosting; processing; transmission and storage; distribution, and LNG. While the work so far has centred on the US industry, GTI’s aspiration to make the protocols applicable across the world.

Regarding LNG, GTI has selected import and export terminals based on companies’ ability to measure and quantify. The organisation has focused on the key emissions sources at these facilities, and has grappled with the difficult issue of quantifying emissions that result from venting, which can be very large but very short in duration.

“You also want to go through and construct an expected emissions distribution, so that you know what you're ultimately going to compare your emissions to, and reconcile with, the measurement,” Moore said.

Protocols for each of the six supply chain segments include:

- Methane Intensity: defines what methane intensities should look like for each segment of the natural gas supply chain;

- Measurement: describes how to take measurements to inform emission inventories by segment;

- Reconciliation: reconciles emission-factor inventories with actual measurements by segment;

- Single value chain summation: adds multiple segments to reach a total emissions intensity; and

- Assurance: provides guidance for verifying an emissions inventory, company documentation requirements and third party auditing.

When it comes to data reconciliation, GTI stresses the need for performing cause analysis across all segments. “If you have large emissions going in, being able to assess the duration of those emissions by performing some type of cause analysis based on your existing understanding of your facility, that's really important,” Moore said.

If a company applies single-event emissions from operations such as venting to longer durations, the emissions will be overestimated. “We want to make sure that we are able to recommend how we define specific point events in time,” Moore said.

“As GTI energy, we put these protocols out there [and] we want to make sure that folks who say they're using these protocols have some way of transparently delivering reports,” he said. Transparency with technology providers and vendors should go “above and beyond,” to demonstrate the accuracy and uncertainties regarding the measurements, he added. “We put a lot of that on the vendor, rather than the company.”