A nuanced approach to emissions mitigation

SUMMARY

Colorado-based consulting firm Tegre advocates for a “nuanced approach” to emissions mitigation solutions in the North American oil and gas industry that allows operators to achieve effective and lasting reductions that are also cost-effective,

By Joseph MurphyPOSTED IN:

Colorado-based consulting firm Tegre advocates for a “nuanced approach” to emissions mitigation solutions in the North American oil and gas industry that allows operators to achieve effective and lasting reductions that are also cost-effective, its director for strategic development, Clayton Nash, tells Gas Pathways.

Established in 2014, Tegre is relatively small in size, but Nash sees this as an advantage.

“We’re small and we want to stay small. We want to grow and be big enough to do more for our clients, but stay small enough to be creative, nimble and lightweight, and so that we don’t lose our culture,” he says.

Those clients are in the US and Canada and range across the upstream, midstream and downstream sectors of the industry. When Nash joined two years ago, he found that while Tegre was doing a lot of emissions mitigation work as part of their various engineering and design projects, “there was an opportunity to package up a lot of the capabilities and methods within the company to make into a standalone service.”

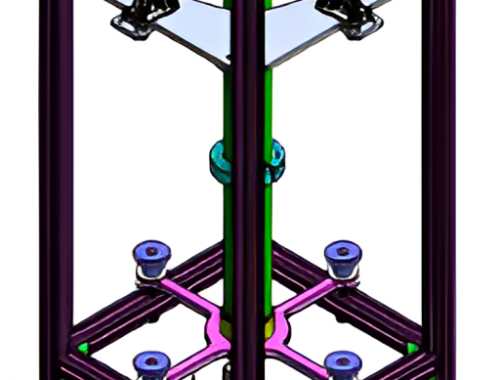

The company’s core business is engineering and design, and today, in addition to emissions solutions, it also focuses on operations support and providing instrument air packages to replace methane-using pneumatic systems and thereby reduce emissions.

“There’s a lot of companies, particularly small and medium-sized owner operator companies that simply do not have the resources in-house to manage their emissions effectively,” Nash explains. “They need external resources to help guide them through this. A lot of the really small companies are dominated by geosciences, drilling and completions expertise, but they don’t have environmental, process, automation, etc. It makes sense, because they don’t need that full time, and that’s a gap to fill.”

Tegre has packaged up all the work that it does to give companies a full cohesive offering. While there is considerable overlap between the company’s engineering and design work and its emissions solutions, a lot of the engineering and design focuses on new facilities, whereas emissions solutions is focused on legacy assets. Currently, emissions solutions is more of a value offering than a value driver, helping Tegre “get its foot in the door” with a new client and gain their trust.

A nuanced approach

The problem faced by the oil and gas industry is that while monitoring and quantification of emissions has gone from weakness to strength in recent years, not enough mitigation is taking place, Nash explains. And often this comes down to a lack of pragmatic solutions.

“When a company detects and monitors their emissions using the amazing technology out there, efforts to solve them often result in one of two extremes,” Nash says. “Either the solution is very low cost but not very effective – equipment that is venting is repaired or replaced but the problem happens again six months later, or the solution is very effective but cost prohibitive, when whole parts of facilities need to be replaced.”

Tegre has a three-tier approach to emissions mitigation solutions. First there are the low-cost quick solutions normally concerning automation controls that can be implemented within a few weeks and cost less than $10,000. The second level involves a few more weeks addressing issues more extensively at a cost of between $10,000 and $100,000. The third level entails rebuilding portions of facilities at costs exceeding $100,000.

“We take this nuanced view and base our solutions around as much as possible what is already there on location,” Nash says. “With minor tweaks of the systems, with some automation and remote monitoring, we can reduce emissions to a level that is not perfect but is pretty good.

First and second level solutions can then be applied to other sites that were built in the same way and likely to have the same issues. Third level solutions can be used when necessary at existing facilities and then be applied to future ones. As its experience increases with every completed job for a client, Tegre becomes better able to pinpoint what the problems likely are without extended assessments, Nash says.

Carrot or stick

Companies come to Tegre for various reasons, both carrot and stick. Sometimes they want to raise the value of their assets by tackling emissions, sometimes it is to comply with existing regulations and sometimes to avoid looming regulations in the future. Sometimes companies recruit Tegre to conduct due diligence or reverse due diligence, when companies are preparing to sell an asset and want to gauge its value better based on its emissions footprint. The focus is on investing in methane mitigation that can ultimately save the company cash – whether by fetching a higher price for their assets or avoiding penalties and taxes.

Some operators are also eager to sign up for certification of their natural gas, through initiatives like Project Canary, MIQ and Equitable Origins. Nash sees big potential for this sphere, which could ultimately lead to some gas being sold for more if it is associated with fewer emissions, or at a discount if it is less clean or kicked out of the market altogether.

“The people that are not going down this path of gas certification are going to have problems – they’re going to lose value on their product, their assets are going to be less marketable. Our private equity clients will have a hard time attracting investment,” he says.

Tegre focuses on a “blue collar approach” to its tasks, Nash says. That involves having personnel with “boots on the ground” to inspect sites with optical gas imaging (OGI) cameras for three or four hours to assess operations over an extended time.

“Sometimes even that is not enough time, so we try to simulate what can happen at a particular location – over one month or two months or in different seasons,” he says “While some companies may be good at developing environmental social and governance (ESG) strategies, a lot of that work is lost if there is not a focus on what is happening directly on the ground, working directly with operating teams and building trust with them.”

Nash’s message to the industry is that there needs to be a “creative, nuanced approach to solving these emissions problems at the ground level one at a time.”

“The innovation in the detection space and new technology is fantastic but we’re not going to innovate our way out of our problem alone. There also need to be practical solutions.”