Tackling methane leaks at the valve: interview

SUMMARY

Control valves are a typical leak point in the natural gas production process, but Clarke Valve's Dilating Disk Valve have been certified to reduce those emissions by up to 98%.

By Joseph MurphyThe CEO of US-based Clarke Valve, Kyle Daniels, lays out the environmental and commercial benefits that the company's Dilating Disk Valve provides. The Dilating Disk Valve has been API 641 and ISO 15848-1 certified to reduce emissions up to 98%, according to the company, and has been tested in the field to prove that emissions are typically eliminated entirely.

In a nutshell, what does the Clarke Valve Dilating Disk Valve offer the natural gas industry? Let’s start with the environmental benefits and move on to the strictly commercial ones? What about the competition?

Kyle Daniels: The Dilating Disk Valve has been field proven over several years and millions of hours of operation to be safe, reliable, and zero emissions. Control valves are typically a natural leak point in the natural gas production process, and by eliminating leaks with the Dilating Disk Valve, we provide the natural gas industry a path to reduce emissions for the company as a whole, while increasing production.

As an equipment supplier of control valves, Clarke Valve’s core mission is to increase efficiency in natural gas production and transmission, while eliminating emissions to zero. We have put an enormous amount of engineering and manufacturing energy into making this possible with every single valve we produce. This should be the goal of all equipment suppliers. This is especially important because our customers are the ones who bear the brunt of governments and the public when it comes to emissions.

If all equipment suppliers put maximum effort into decreasing emissions to zero, as an industry we could prevent millions of tons of natural gas, which is 98% methane, from escaping to the atmosphere. Natural gas doesn’t do anyone any good in the atmosphere; all valve manufacturers should be focused on keeping natural gas in the pipe until it can be utilised.

If we take the environmental benefits out of the equation, does the strictly commercial benefit stand on its own as a reason for adopting the valve?

When the gas isn't escaping in the form of fugitive emissions, there's only one other place it can be: in the pipeline. By preventing these fugitive emissions, the Dilating Disk Valve is increasing the amount of gas that remains in the pipe from Point A to Point B, bolstering production. We have analysed field data from our customers showing consistent increases in natural gas production just by switching to the Dilating Disk Valve. More production means more revenue, and more clean energy.

In the 2022 survey conducted in this magazine, 58% of respondents said increasing machinery performance was the most desirable way to maximise the investment in critical machinery. That makes a lot of sense. Equipment should be designed to maximise the performance of all installed machinery in the natural gas value chain.

In the same survey, 80% of respondents said that reliability was the most important thing when it comes to gas compression equipment. Dilating Disk Valves, since they are zero emissions, reduce maintenance and increase reliability, since no repairs or adjustments are required during LDAR inspections.

The truth of the matter is that it’s actually very simple to prevent emissions. There are thousands of industrial processes that require zero leakage. The engineering know-how to do this has been around for a long time.

In the field of methane monitoring, quantification and mitigation – would you agree that the innovations in mitigation have sometimes been overlooked in comparison to those regarding monitoring and quantification?

Every aspect of reducing emissions is important to consider, and each has its own role in the big picture. Quantification and monitoring helps us find out where the problems lie, but installing technologies that are inherently zero emissions is not just good for the environment, it's good business. The natural gas industry has not overlooked mitigation technologies, and we are well received around the world. The main problem is that there aren’t that many field proven, reliable and widely available products on the mitigation side, but we’re doing our part to change that.

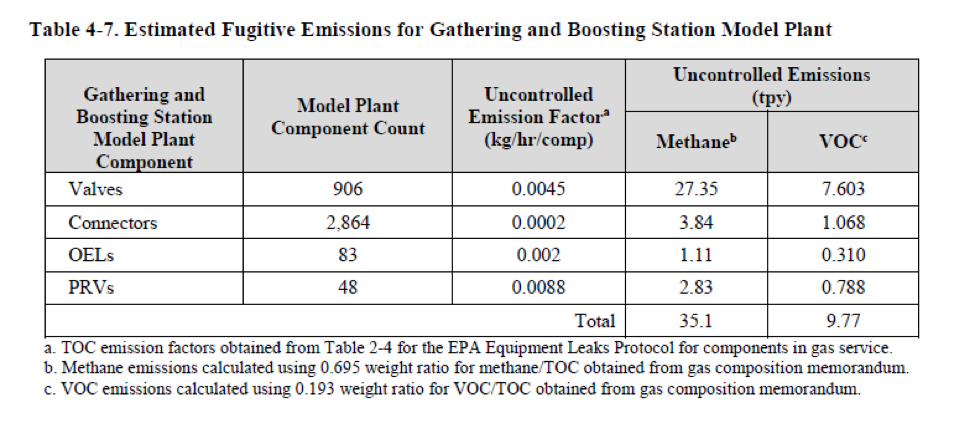

As you can see from this table in the latest EPA methane regulations, valves are by far the leading cause of uncontrolled emissions. This is why the Dilating Disk Valve is so important to the natural gas industry and the environment as a whole.

What is primarily driving industry operators to adopt technology like that offered by Clarke Valve? Is it regulatory pressure or individual company incentive?

The Dilating Disk Valve has been proven safe and reliable over years of testing in the field, and the fact that they are made to the highest specifications of safety, have a "plug and play" design for easy installation, and can be purchased and installed at no net additional cost to the customer are major factors in why we've had success. External factors such as regulations and individual company goals surely have some impact, but the fact is the Dilating Disk Valve is more cost effective, boosts production, and is reliable. This is what ultimately drives adoption.

Is there some lethargy in some areas of the industry to adopting equipment that is readily available to reduce emissions?

The natural gas industry deals with hydrocarbons moving at high pressures throughout the production process, which means that companies are very focused on safety and reliability. Each company prefers to collect their own data, and during that process they learn more about the potential for valves like the Dilating Disk. There is an appetite for innovative technologies like these especially since the technology in use today was typically designed many decades ago. Much of the time it takes to begin adopting better technology is simply the time required to demonstrate safety and reliability in the field, something Clarke Valve has been doing very successfully over the last several years.

Clarke Valve has of course had backing from the OGCI Climate Investments fund. In your view, how difficult is OGCI CI’s screening process for new investments to pass through? Beyond financial support, how has Clarke Valve’s relationship with OGCI benefited the company?

The screening process is rigorous, and for good reason. Major producers of oil and gas, 12 of which are members of OGCI CI, are looking for innovative technologies with strong potential to revolutionise the industry. However, any technology being considered must have a stellar safety and reliability record. In working closely with OGCI member companies over the last several years, we have advanced our technology by leaps and bounds, which accelerated our maturity for scaled up installation. Working this closely with so many partners in the natural gas industry would have been nearly impossible without the support of OGCI.

Let’s talk about Clarke Valve’s business in numbers. What has been the growth trajectory so far and what ambitions does the company have in the near and mid terms?

Clarke Valve has scaled up production several times in the past and we’re scaling up again. Our technology is mature, safe, and proven to remain zero emissions in the field while simultaneously boosting production. We are at the perfect inflection point of policy and technology. Governments are finally coming around to offering incentives rather than penalties. Companies can now look to zero emissions technologies like the Dilating Disk with support of government incentive programs like the United States’ Methane Emissions Reduction Program. Government incentives provide a major opportunity for businesses to upgrade their technologies while simultaneously doing good for the environment.

Where is Clarke Valve’s business geographically and what aspirations does the company have to expand?

Clarke Valve is based in the Northeast of the US, surrounded by an industrial base of companies including foundries, machining suppliers and many large-scale manufacturers. We currently have a customer base on 5 continents around the world. Our growth is going to be based on how quickly we can scale up production and how much we can expand our installed base with new and existing customers. We have a very exciting value proposition while helping companies meet their internal and external goals. This is proving to be a winning combination.